03

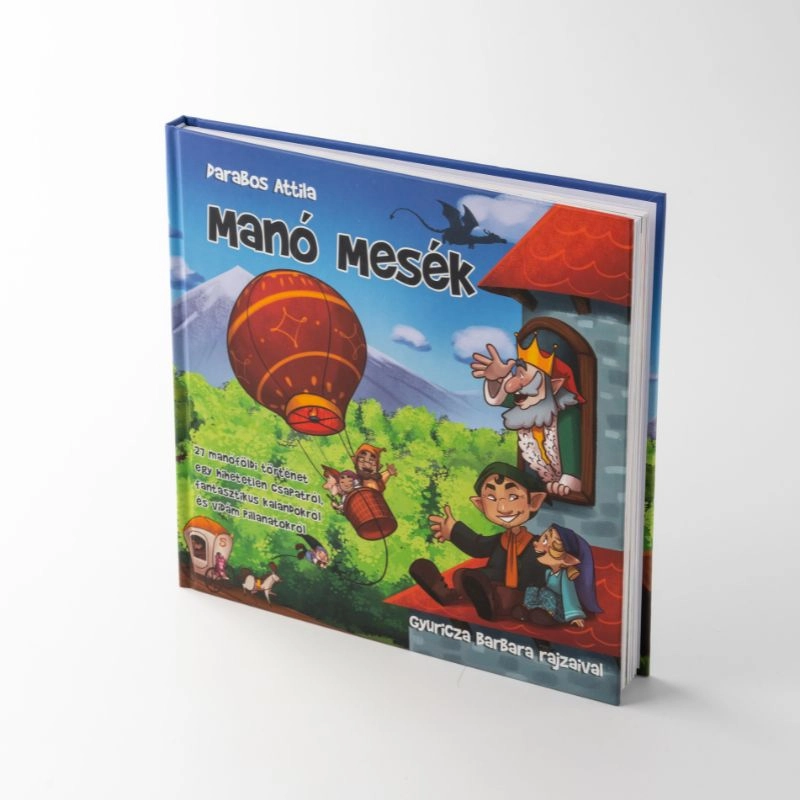

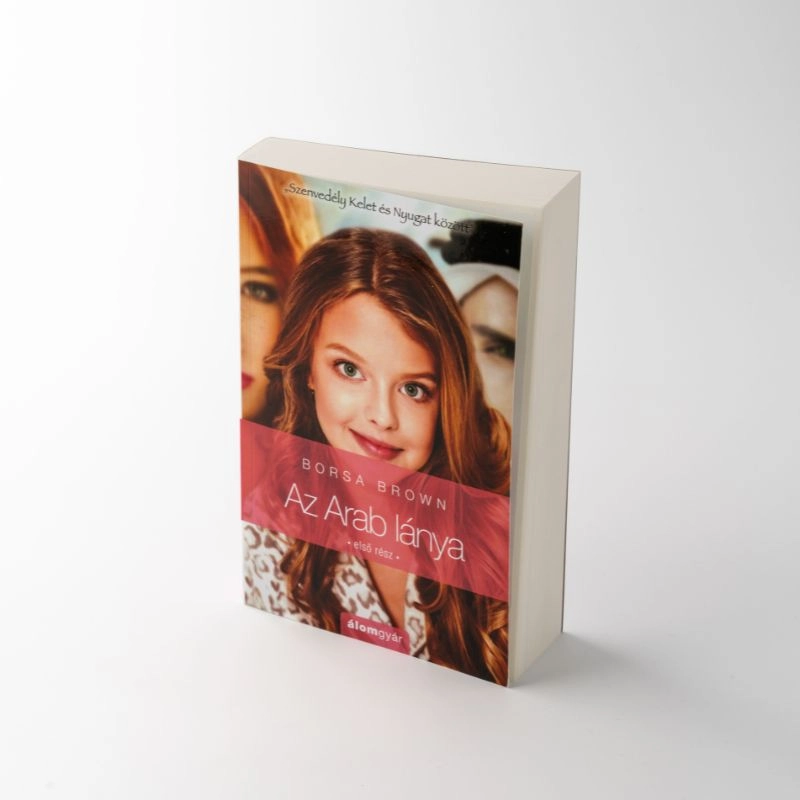

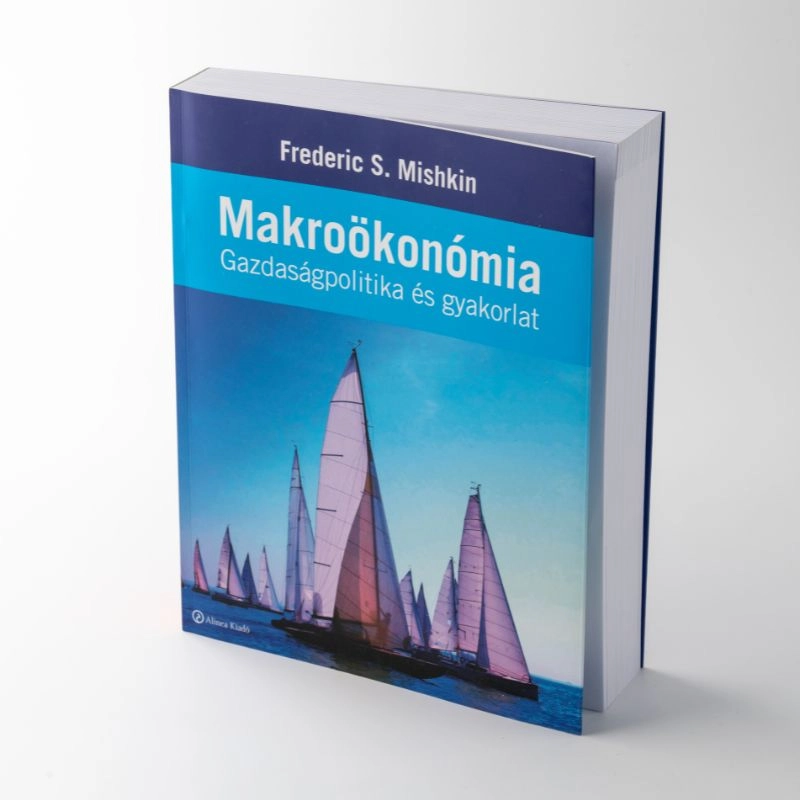

Production of paperboard and hardcover books and publications using high quality roll inkjet technology, ultra-fast mileage, customizable prints and an environmentally friendly process.

FSC and ISO certifications

flexible manufacturing options

short lead time

small and medium number of orders - optimization of storage costs

same quality as offset technology

common, traditional types of paper

water-based, environmentally friendly paints

30 years of experience in digital roll printing

reliable, experienced professional background

On the surface of the cover, glossy or matte parts are highlighted with varnish.

Letters, graphic elements are embossed from the surface of the printing medium without the help of a cliche, digitally.

We use coloured foil to press the print substrate onto the desired surface to create a shiny, metallic effect.

Formal varnish containing metallic pigments is applied to the surface of the cover.

EPDB Nyomtatási Központ Zrt. is FSC® CoC certified. The FSC® (Forest Stewardship Council) aims to ensure that the production of wood products comes from environmentally sound, socially beneficial, economically sustainable forest management. The FSC certificate also guarantees that we use products from sustainable forest management, and that the wood we process does not come from illegal logging, high conservation value forests or genetically modified plantations.

In our printing, we use water-based inkjet inks. These environmentally friendly paints do not contain any hazardous substances, can be washed with water and do not require additional chemicals during use.

The waste generated during offset printing (ink residue, dye wrappers, various detergents) is all classified as hazardous waste.

The water-based inkjet inks used in the EPDB Nyomtatási Központ Zrt. do not contain hazardous substances, so emptied plastic ink tanks are not considered hazardous waste.

Digital printing generates much less waste in the adjustment process compared to offset. Due to the lower starting cost, there is no need to produce large quantities of copies, some of which may end up in the trash, in the best case recycled.

Inkjet printing can be carried out at much lower temperatures, much less energy is required for drying, which also reduces the heat load on the environment.

Szeretettel várunk a standunknál!